In complex geotechnical environments, standard reinforcement often fails to provide the reliability needed for safe operation. Hollow rock bolts offer a customizable, high-performance solution that adapts to varied and demanding applications.

Hollow rock bolts are commonly used for tunnel support, slope anchoring, and underground excavation due to their strength, installation efficiency, and system compatibility.

With growing infrastructure needs, engineers and procurement teams are increasingly seeking solutions that combine performance, cost-effectiveness, and flexibility.

What makes hollow rock bolts different from traditional solid bars?

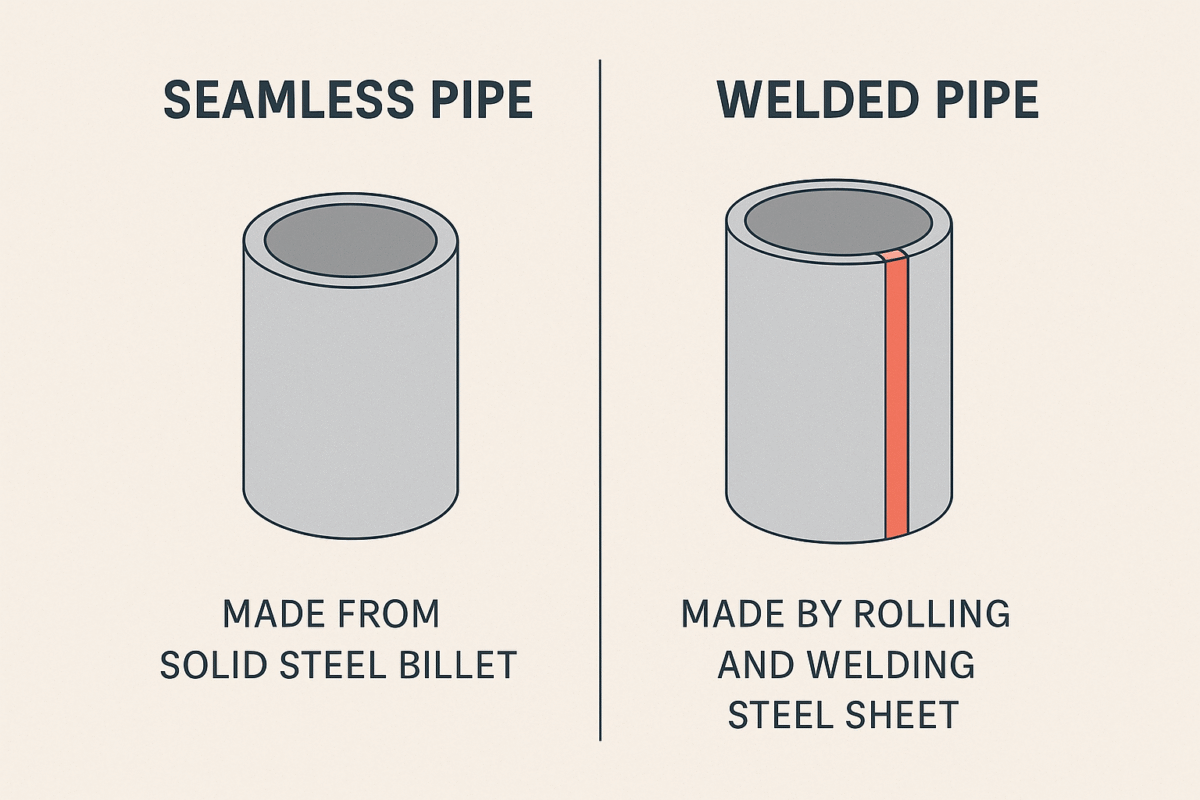

Compared to traditional reinforcement bars, hollow rock bolts allow grout to be injected through the bolt itself, ensuring more uniform anchorage and simplifying installation—especially in unstable strata or narrow spaces. The hollow design also contributes to weight reduction and ease of handling on site.

This design improves bonding with surrounding material and allows for full-length grouting, offering higher security and lower risk of voids during installation.

Can these bolts be customized for different project needs?

Absolutely. While there are general reference sizes widely used in mining, tunneling, and civil projects, we provide fully customizable solutions tailored to your required dimensions, strength level, and performance outcomes.

Whether you’re working with specific geotechnical parameters, facing unique borehole diameters, or requiring enhanced impact resistance, we work with you to configure a solution that fits.

What performance benefits do they bring to demanding environments?

Hollow bolts are often chosen for their excellent impact resistance, tensile strength, and ductility. In underground or slope reinforcement scenarios, they play a vital role in controlling deformation and preventing collapse. They are also compatible with most anchoring systems and easy to combine with drill-and-grout equipment.

Because of their uniform wall thickness and dimensional consistency, they offer more predictable load transfer and safer long-term performance. Their surface can also be treated to increase corrosion resistance in aggressive environments.

Conclusion

In demanding conditions like tunneling, mining, and slope stabilization, selecting the right anchoring system can directly impact safety and efficiency. Hollow rock bolts offer a well-rounded solution—strong, efficient, and customizable. Whether you’re an engineer or a project buyer, reach out to explore how we can support your specific application needs.