Need something strong, neat, and easy to build with? Square tubing might just be the Lego block of industrial design.

Square steel tubing is a versatile structural material used in everything from machinery frames to construction supports. Engineers prefer it for its clean geometry, weldability, and load-bearing efficiency.

Let’s unpack why square tubing remains a favorite across industries—and how it could be the missing piece in your next project.

Where is square steel tubing used?

Imagine building a shelf from scratch. What shape would make it sturdy, balanced, and easy to bolt together?

Square tubing is widely used in agriculture, construction, machinery, and fabrication. Its flat sides make it easy to mount, weld, or connect—ideal for both light and heavy-duty structures.

Square steel tubing acts like the frame of a house—it doesn’t move, twist, or bend easily. Its four equal sides make it ideal for use in machine frames, worktables, trailers, building supports, and agricultural equipment.

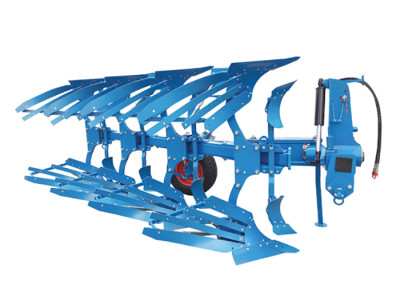

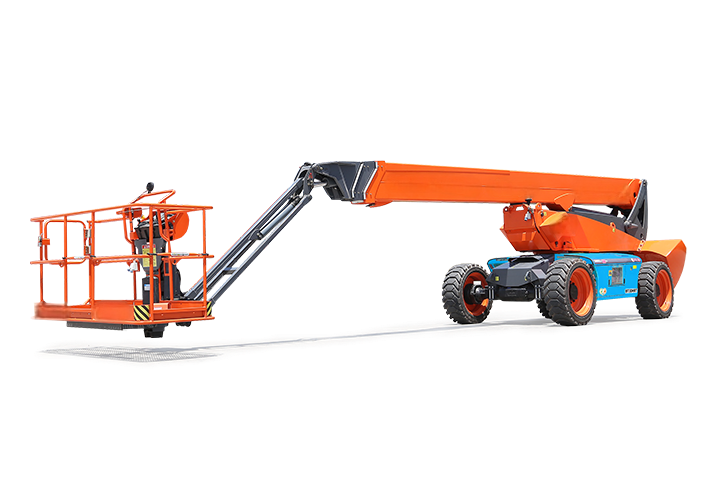

In farming machines, it helps create simple, strong frames that can be welded or bolted easily. In construction, square tubes are often used in gates, fences, and scaffolding, where stability and visual symmetry matter.

Unlike round pipes, which are great for carrying fluid or resisting internal pressure, square tubes are designed for structural integrity. They resist bending in all directions, making them ideal for building straight and square systems.

You’ll even find square tubing in furniture design, storage systems, and architectural frameworks—anywhere a clean, modular, modern look is needed.

Why do engineers prefer square tubing?

It’s not just about looks. Square tubing offers more than symmetry—it offers engineering logic.

Engineers choose square tubing because it’s easier to connect, aligns well in builds, and offers excellent strength-to-weight ratios—especially when welded into frames.

Flat surfaces make fabrication simple. You can place a square tube on a flat table and it won’t roll away—unlike a round pipe. This alone saves time and reduces alignment errors during welding and assembly.

The even distribution of material across all four sides makes it resistant to torsion and bending. That means it can take loads from any direction—an ideal property for load-bearing frames and pressure-resistant structures.

Plus, square tubing nests well. Engineers love using telescoping tubes—sliding one inside another—for adjustable or retractable frames. This is harder to do with round tubes, which often deform or need special tools for tight nesting.

If tight tolerances and consistent performance are critical, engineers often request cold-drawn square tubing, which offers superior dimensional accuracy and surface finish. (Learn more in our Cold Drawing Explained)

What are the advantages of square tubing over other shapes?

Think of square tubing as the goldilocks shape—not too flat, not too round, just right.

Compared to angle iron or round pipes, square tubing offers better resistance to bending, easier mounting, and a cleaner aesthetic for visible builds.

While angle bars are great for bracing, they only support stress in specific directions. Round pipes resist internal pressure but are harder to weld onto flat surfaces. Square tubing finds a sweet spot: four uniform sides that provide both balance and strength.

It’s also easier to measure and cut. Need a 90-degree weld? No problem—the corners line up naturally. Need to drill holes for bolts? You get a flat surface to work with.

From a cost perspective, square tubing can be more material-efficient in structural builds, especially when weight matters but appearance and alignment can’t be sacrificed.

Conclusion: Why you might need square tubing next

Square steel tubing is more than just a building material—it’s a design solution. Whether you’re an engineer, a fabricator, or a purchasing manager, it delivers consistency, strength, and simplicity in one clean profile.

Ready to find the right square tubing for your project?

Let’s make it simple: tell us your specs, and we’ll match you with the perfect material—custom sizes, tolerances, and finishes included.

Check out our square tubing product page or contact us directly to start your project today.