Struggling to decide between seamless and welded steel pipes? You’re not alone – many buyers find the difference confusing.

If you’re not sure whether to buy seamless or welded steel pipes, this guide will help you choose the right one based on your project needs.

Most buyers aren’t steel experts — they rely on engineers or standards. But choosing the right pipe can affect cost, delivery, and performance. Let’s make that decision easier.

What’s the difference between seamless and welded pipes?

Think all steel pipes are the same? The way they’re made tells a different story.

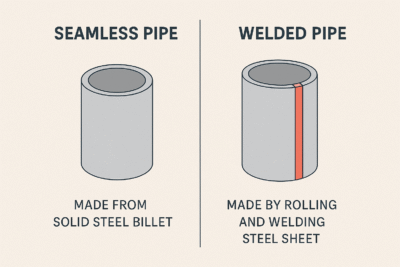

Seamless pipes are made from a solid billet and have no weld seam, while welded pipes are made by bending and welding a flat steel plate.

Dive deeper:

The main difference lies in the manufacturing method:

| Feature | Seamless Pipe | Welded Pipe |

|---|---|---|

| Production | Made from solid steel billet | Made by rolling and welding steel sheet |

| Weld seam | No weld seam | Has a visible and internal weld |

| Pressure resistance | Higher | Lower compared to seamless |

| Cost | Higher | Lower |

| Availability | Flexible for small orders | Cost-effective in bulk |

| Size accuracy | High (especially with cold drawn method) | Moderate |

Seamless pipes are often preferred for critical applications—like high pressure, high temperature, or precision systems—because they have uniform strength and no weak weld line. Welded pipes, while more affordable, are limited by the quality of the weld and usually need additional tests or treatments for demanding uses.

When should you choose seamless pipes?

Need strong, precise pipes for a small project? Seamless might be your only option.

Choose seamless pipes for high pressure, high precision, or small-batch orders.

Dive deeper:

Seamless pipes are your best bet when:

- You need tight dimensional tolerances (like hydraulic systems or custom assemblies).

- You’re dealing with high pressure or temperature (such as boilers, heat exchangers, or refineries).

- The project requires small quantities – most welded pipe manufacturers set high minimum order quantities, but Yige Steel’s cold drawn seamless pipes support flexible, small-batch orders.

- You’re concerned about corrosion starting at the weld seam (especially in chemical applications).

In addition, the cold drawn process we use allows us to control pipe diameter and wall thickness to very tight tolerances—ideal for applications like auto parts, fluid transport systems, and more.

When is welded pipe a better choice?

Working with tight budgets or large-scale projects? Welded pipes might save you money.

Welded pipes are suitable for low-pressure, large-scale, and non-critical applications.

Dive deeper:

Choose welded pipes when:

- You’re buying in large quantities and cost is a concern.

- The application is non-critical — such as fencing, construction scaffolding, or cable conduit.

- You’re working with larger diameters, especially above 16 inches, which are often easier to find in welded form.

- Delivery time is urgent — welded pipes are usually more readily available from stock.

Still, keep in mind that the weld seam could be a weak point under extreme conditions. For industries with strict quality requirements, the weld zone often needs extra testing (like ultrasonic or radiographic inspection).

If you do go for welded, make sure it meets the standards like ASTM A53, EN 10217, or others relevant to your industry. Or, ask your supplier (like us 😉) to guide you based on your drawings and specs.

What should a buyer pay attention to when choosing?

Confused by specs and standards? Focus on the job, not the jargon.

Start by asking what the pipe needs to do – then decide based on pressure, precision, quantity, and budget.

Dive deeper:

Here are a few smart questions to ask before choosing:

- What pressure and temperature will the pipe face?

- Do I need tight tolerances or exact fit?

- Is this for a critical system, or general use?

- What’s my budget and order volume?

- Are there any certifications or standards I must follow?

If your engineer gave you a spec sheet but you’re unsure how to match it to real products, feel free to share it with our team. We’ve helped buyers from Germany, the U.S., and France interpret EN/DIN/ASTM specs and pick the right seamless pipes that match their drawings and needs.

Conclusion

If you’re choosing between seamless and welded pipes, think beyond just the price. Seamless pipes offer superior strength, precision, and flexibility—especially for small batches and critical jobs. Welded pipes work for larger volumes and lower-risk uses.

At Yige Steel, we specialize in cold drawn seamless steel tubes that meet global standards and small quantity needs. Let us know your specs—we’ll guide you to the right solution.