Product Specifications

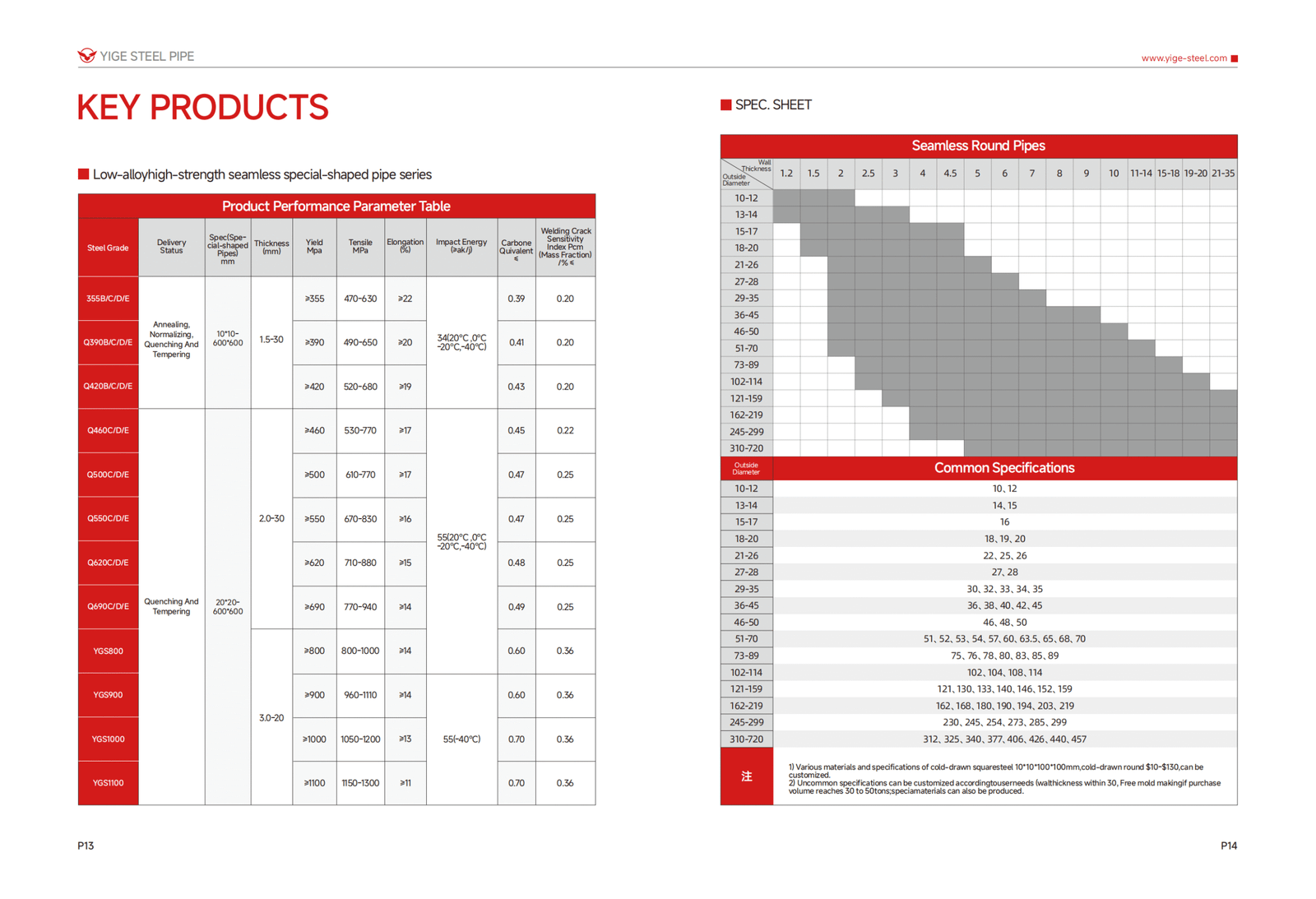

| Parameter | Details |

| Material Grades | Q345,Q355,Q390,Q420,Q460,Q500, Q550, Q620, Q690, Q960 (Custom alloys available) |

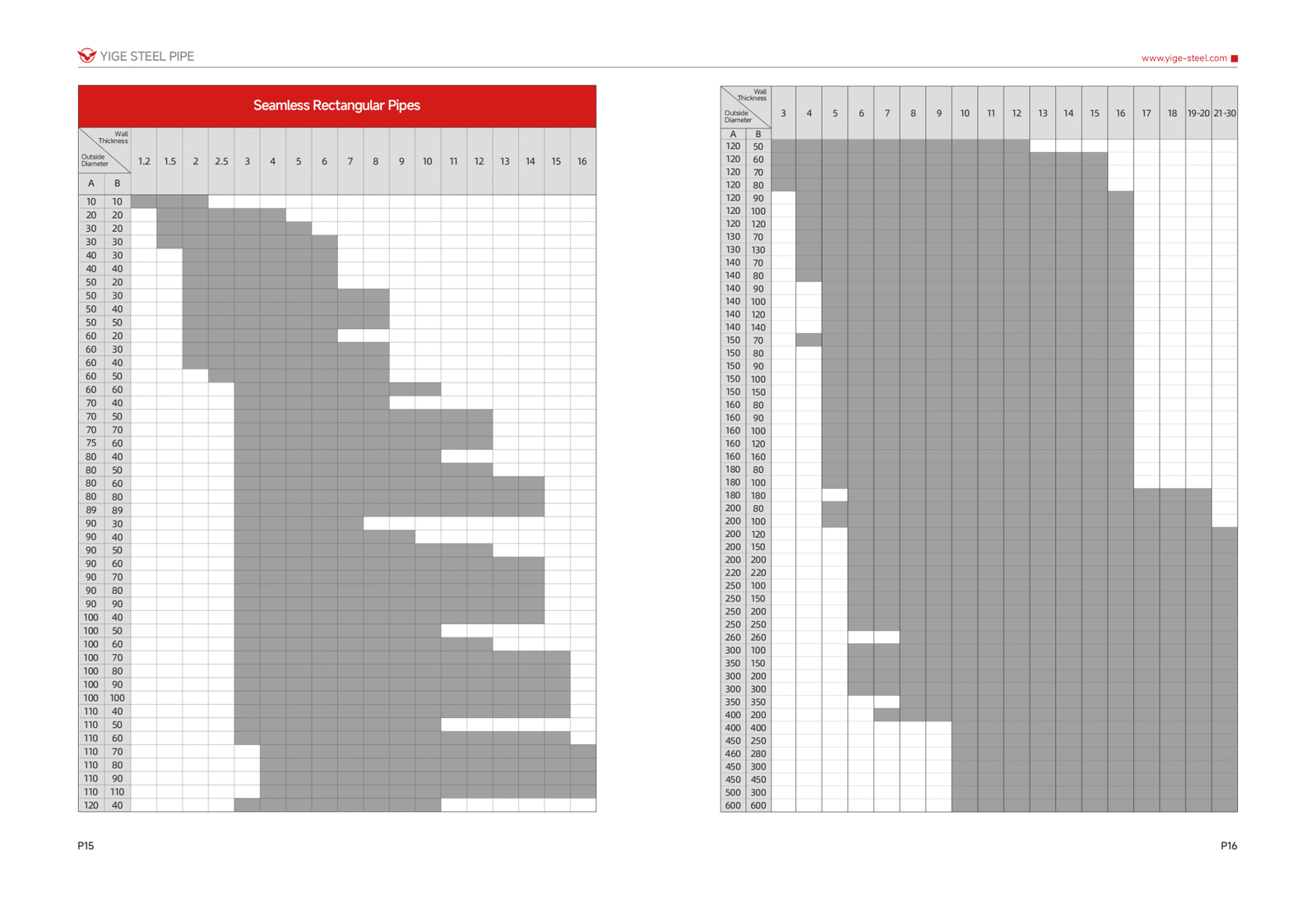

| Shape | Round, square, Rectangular or any other special shaped |

| Yield Strength | 345-1000 Mpa (Test reports available) |

| Out diameter(OD) | 10-600mm, other sizes negotiable |

| Wall Thickness(WT) | 1.2-30mm, other sizes negotiable |

| Length | Up to 16m |

| Standards | GB/T 3094-2012, GB/T 1591-2008,EN 10210 |

| Delivery Condition | Cold-drawn, Q&T (Quenched & Tempered), Normalized |

| Payments Term | T/T or L/C |

| MOQ | 1 ton |

Production Description

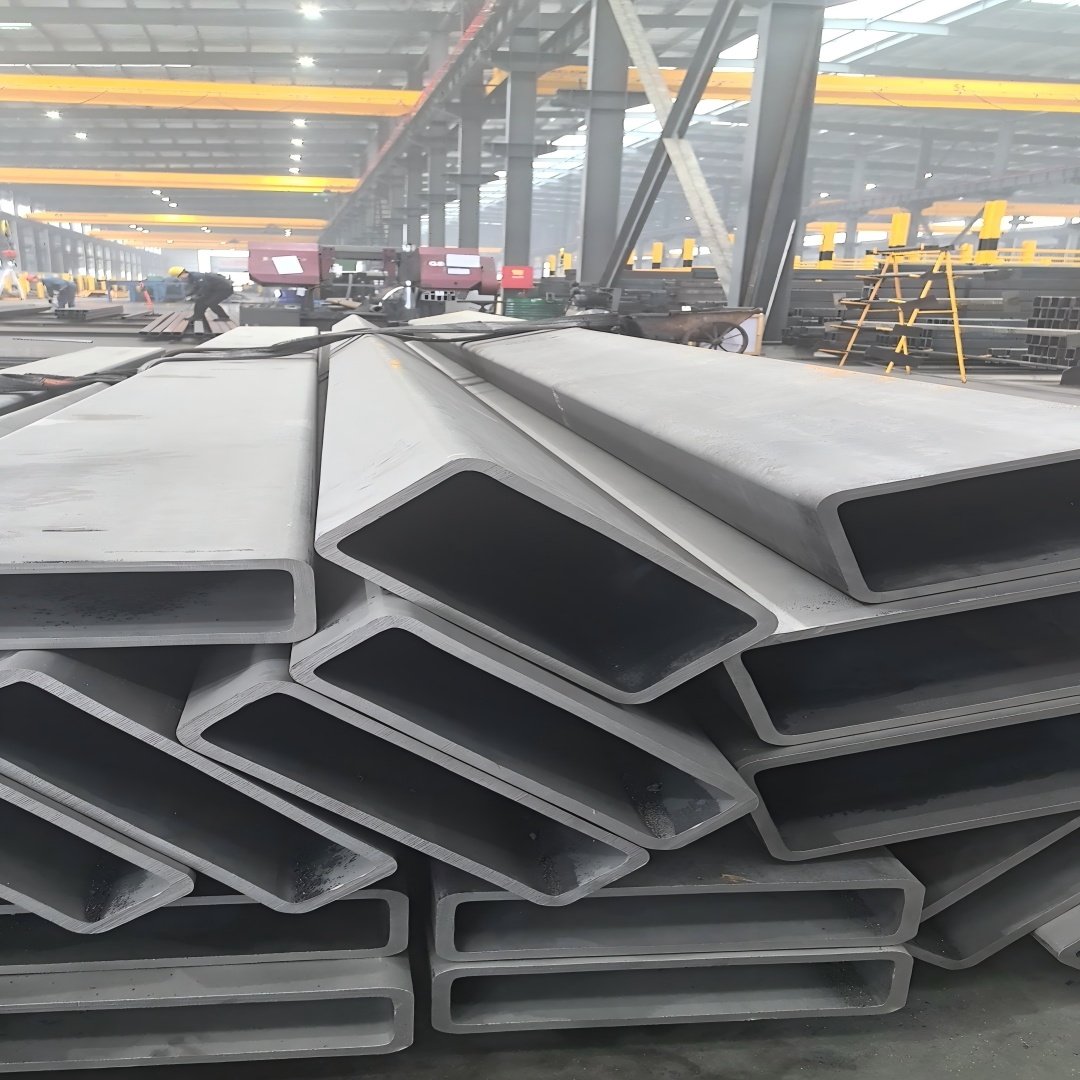

We supply high-quality seamless steel pipes, formed from round seamless tubes through cold drawing processes. These pipes feature uniform structure, high dimensional accuracy, and smooth surface finish, making them ideal for structural and precision machining applications.

Our seamless pipes offer excellent compressive strength and bending resistance, widely used in structural engineering, machinery manufacturing, container frames, agricultural equipment, and automotive chassis. Customization is available for specific lengths, cutting, and anti-corrosion coatings.

With in-house mold development and technical support, we ensure short lead times and third-party inspection options to meet diverse global customer requirements.

Key Features

|

1.High Yield Strength |

With yield strength ranging from Q345 to Q960 MPa, our pipes withstand greater stress without permanent deformation—offering 30% more strength than standard steel pipes. This makes them ideal for demanding structural and pressure applications. |

|

2.Lighter Weight, Same Load Capacity |

High strength-to-weight ratio allows the use of thinner and lighter pipes while maintaining load performance—reducing material cost and transport weight. |

|

3.Outstanding Fatigue & Cryogenic Resistance |

Engineered for extreme environments, these pipes retain impact resistance at temperatures as low as -60°C. Widely used in offshore platforms, mining, and cold-region installations. |

|

4.Superior Consistency and Processability |

Produced via cold-drawn + Q&T (Quenched and Tempered) processes, the pipes feature uniform grain structure and mechanical performance—perfect for precision assembly and automated welding. |

|

5.Customizable Shapes and Sizes |

Available in round, square, rectangular, and special shapes. Supports non-standard dimensions, thick/thin walls, and extended lengths—tailored to your project needs. |

|

6.Longer Service Life |

Compared to welded pipes, high yield seamless pipes deliver up to 30% longer lifespan under the same working conditions, providing superior value over time. |

Application

| Oil & Gas Industry | Pipeline systems for transporting oil, natural gas, and petroleum products

Drill collars, risers, casing, and tubing for high-pressure environments |

| Offshore & Marine Structures | Subsea pipelines, jacket structures, and legs of offshore platforms

Components exposed to harsh marine environments requiring high strength and corrosion resistance |

| Construction & Infrastructure | High-rise buildings, bridges, and structural supports requiring superior load-bearing capacity

Reinforcement for tunnels and seismic-resistant constructions |

| Automotive & Heavy Equipment | Axle tubes, suspension systems, and chassis components

High-load-bearing parts for construction and mining equipment |

| Power & Energy | Boilers and heat exchangers operating under high pressure and temperature

Structural piping in thermal, nuclear, and renewable power plants |

| Defense & Aerospace | Military vehicles, armored tubes, and high-strength frame structures

Lightweight yet strong structural parts requiring excellent performance under dynamic loads |

Available Mold

Customization

With in-house tooling, material sourcing, and technical support, we offer flexible customization to meet your specific needs:

- Dimension Customization: Non-standard diameter, thickness, and length

- Material Options: Carbon steel, stainless steel

- Processing Services: Cutting, logo marking

- Surface Treatment: Painting, shot blasting, oiling, galvanizing

- Marking & Packaging: Custom logo, labels, and packaging options

We support drawing-based production, small batch trial orders, and fast sample delivery to help your projects start quickly.

Product Inspection

- Inspect the outer diameter

- Inspect the zine amount

- Inspect the thickness

- Mechanical property

- Metallography testing

- Chemical composition analysis

- Non-destructive testing

- Salt spray test

Testing Equipment

- Universal Servo Tensile Testing Machine

- Charpy Impact Testing Machine

- Direct-Reading Spectrometer

- Salt Spray Test Chamber

- Vickers Hardness Tester

- Metallurgical Microscope

Packaging & Delivery

We provide professional packaging and flexible delivery options based on your product and shipping needs:

- Packaging Methods:

- Steel-strapped bundles with labels

- Plastic wrap + woven fabric cover

- Export-grade wooden cases or pallets

- Plastic end caps for tube protection

- Delivery Options:

- Sea freight, truck transport, or rail shipment

- Common ports:

- Shanghai, Changsha

- Lead Time:

- Standard sizes: 7–15 days

- Custom orders: 30–45 days

Export documents such as CO, CQ, and third-party inspection reports are available upon request.

CTA Section

Get Your Custom Quote in 24 Hour

FAQ Section

Q1: How could you guarantee your products?

A1: Each piece of products is manufactured by certified workshops, inspected by piece according to national QA/QC standard. We also could issue the warranty to customer to guarantee the quality.

Q2: Can we visit your factory?

A2: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

Q3: Are you a factory or trading company?

A3: We are manufacturers and also do export trade.

Q4: Can I get some samples?

A4: Yes, We are pleased to provide you with samples of our products.

Q5: How about MOQ?

A5: We have stock for common sizes at hand, so one ton per size is acceptable.

Reviews

There are no reviews yet.