Alt: Agricultural machinery with steel pipe improving efficiency and cost-effectiveness

Steel pipes are more than structure — they shape cost, strength, and long-term efficiency.

Whether you’re designing a new rotary tiller or sourcing parts for a harvester, steel pipe choices directly affect agricultural machine performance and cost. Let’s explore how the right pipe makes a lasting difference in farming equipment.

What Role Does Steel Pipe Play in Agricultural Machinery?

Steel pipe in agricultural machinery isn’t just a frame. It’s embedded in:

- Drive shafts

- Hydraulic cylinders

- Slide rail systems

- Frame support structures

Depending on the application, you might need:

- Round pipe for shafts and fluid systems

- Square pipe for frames

- Custom-shaped pipe for fitting into unique mechanical structures

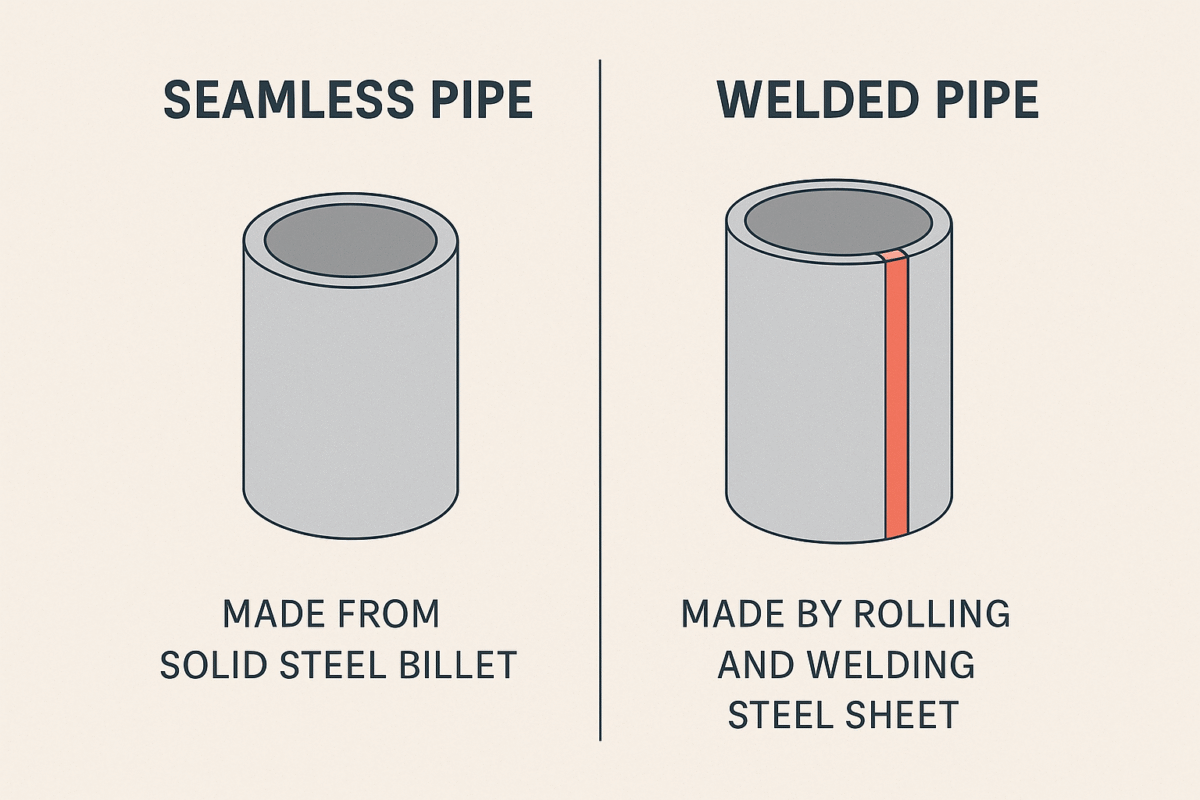

See also: Seamless vs Welded Steel Pipe – What’s Better for You?

How Steel Pipe Lowers Machine Cost

1. High Strength Means Thinner Walls

Using high-strength grades like Q550 or Q690 allows you to reduce wall thickness while maintaining durability—resulting in less raw material and lower overall cost.

2. Custom Shapes Reduce Assembly Time

Instead of multiple welded pieces, one custom-formed steel pipe can simplify structure, cutting labor and welding costs.

3. Lower Maintenance and Replacements

Durable pipe = fewer breakages. Machines last longer, repairs decrease.

Custom steel tube solutions like these can reduce welding costs and maintenance.

How Steel Pipe Improves Efficiency

➤ Lighter Machines, Lower Fuel Use

Every gram counts. A lighter yet stronger structure reduces fuel consumption and improves maneuverability.

➤ Precision Manufacturing

Custom or cold-drawn pipes allow tight tolerances, saving you time in installation and improving fit.

➤ Smoother Machine Performance

Good pipe = good alignment = reduced vibration = longer component life.

Example: One Change, Big Impact

A client producing agricultural tillers replaced a welded square frame with custom high-strength square steel pipe. Though no specific numbers are disclosed, the impact included:

- Easier assembly

- Lower raw material waste

- Greater durability in fieldwork

Their comment?

“We didn’t expect changing the pipe would make the whole machine more efficient.”

Choosing the Right Pipe

Here are a few tips when sourcing steel pipe for agriculture:

| Feature | What to Look For |

|---|---|

| Strength | Yield strength Q355 to Q690, depending on load |

| Shape | Match the function (round for shafts, square for frame) |

| Wall Thickness | Optimize for weight vs strength |

| Surface Treatment | Rust protection is a must |

| Supplier Capability | Customization, fast lead time, mold design |

Conclusion

When it comes to farming equipment, steel pipe isn’t just a part—it’s a performance factor. Choosing the right pipe impacts cost, efficiency, and machine lifespan.

If you’re rethinking your component strategy, start with the pipe. You might be surprised how much it matters.

Explore our agriculture-focused steel pipe solutions or contact us directly for consultation.

Meta Description

Discover how steel pipe impacts the cost and efficiency of agricultural machines. Learn how the right pipe choice can reduce costs, improve performance, and extend machine life.