Are you sourcing precision steel tubes for hydraulic cylinders, automotive components, or high-performance machinery? Choosing the right EN 10305 standard can feel confusing — EN 10305-1, EN 10305-2, EN 10305-3, EN 10305-4, EN 10305-5… what’s the difference?

The EN 10305 series defines the quality, dimensions, and manufacturing processes for precision steel tubes in Europe. Understanding these standards helps importers, engineers, and purchasing managers ensure the right fit for their projects.

What is EN 10305?

EN 10305 is a European standard for precision steel tubes, covering both seamless and welded types. Unlike general structural pipes, EN 10305 emphasizes:

- Tight dimensional tolerances (e.g. H8 inner diameter)

- Smooth surfaces for sealing and assembly

- High mechanical properties for safety-critical parts

That’s why EN 10305 tubes are widely used in:

- Hydraulic and pneumatic systems

- Automotive components (chassis, steering, shock absorbers)

- Engineering machinery and precision equipment

EN 10305-1: Seamless Cold Drawn Precision Tubes

- Type: Seamless

- Process: Hot rolled seamless tube → cold drawn

- Applications: Hydraulic cylinders, automotive steering systems, mechanical precision parts

- Features: High accuracy in size and mechanical strength

EN 10305-2: Welded Cold Drawn Precision Tubes

- Type: Welded

- Process: Welded tube → cold drawn for precision

- Applications: Automotive, mechanical structures, hydraulic lines

- Features: Cost-effective vs seamless, dimensional tolerance up to H8

EN 10305-3: Welded Precision Steel Tubes (As-Welded)

- Type: Welded (not cold drawn)

- Applications: Automotive body parts, general machinery

- Features: Lower precision than -2, but cheaper and suitable for structural purposes

EN 10305-4: Seamless Precision Tubes for Hydraulic & Pneumatic Systems

- Type: Seamless cold drawn

- Applications: Hydraulic cylinders, pneumatic actuators

- Features: Strict requirements on inner surface finish (often Ra ≤ 0.8 μm), cleanliness, and pressure resistance

- Note: This is the most common choice for hydraulic tube importers

EN 10305-5: Welded Cold Sized Precision Tubes

- Type: Welded + cold sized (not full cold drawn)

- Applications: Automotive chassis, structural parts

- Features: Good for automotive industry, balances precision and cost

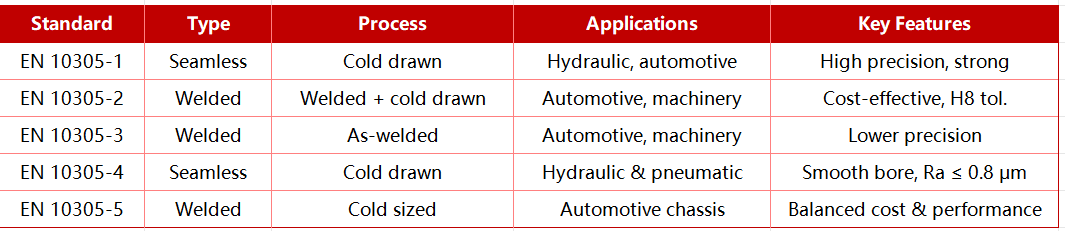

Comparison Table of EN 10305 Standards

Why EN 10305 Matters for Importers

- Compliance: EN 10305 is widely recognized in Europe and global markets.

- Quality Assurance: Guarantees dimensional accuracy and mechanical properties.

- Application Matching: Right choice reduces cost and ensures performance (e.g., EN 10305-4 for hydraulics).

Internal Links

Conclusion

The EN 10305 series provides a reliable framework for choosing precision steel tubes. Whether you need high-pressure hydraulic tubes (EN 10305-4), cost-effective cold drawn welded tubes (EN 10305-2), or automotive chassis tubes (EN 10305-5), there’s a specific part of EN 10305 designed for your project.

At YIGE Steel, we supply both seamless and welded precision tubes, certified under CE, ISO, and BV standards. Contact us to find the right EN 10305 solution for your application.