Confused by Chinese steel pipe standards like GB/T 8163? You’re not alone—many international buyers struggle to decode what these codes really mean.

GB/T 8163 is China’s national standard for seamless steel pipes used to transport fluids. This guide explains what it covers, how it compares to ASTM standards, and why it matters.

Whether you’re sourcing pipes for an industrial project or fulfilling specs from your engineering team, understanding this standard will help you make informed and cost-effective decisions.

1. What does GB/T 8163 cover?

Ever wondered if Chinese seamless pipe standards are equivalent to ASTM or EN specs?

GB/T 8163 specifies the technical requirements for seamless steel tubes used for conveying fluids such as water, oil, gas, and steam.

Dive deeper:

GB/T 8163 is one of China’s most commonly used standards for seamless pipes not used in pressure vessels or boilers. It is part of the GB (Guobiao) family of standards and focuses specifically on fluid transmission under normal working pressure and temperature conditions.

Key scope highlights:

- Covers cold drawn, hot rolled, and hot expanded seamless steel tubes

- Designed for fluid transport, such as oil pipelines, chemical plants, and city heating systems

- Excludes applications like high-pressure boilers (covered under GB/T 5310) or structural use (GB/T 8162)

2. Comparison with ASTM A106 and EN 10216

| Feature | GB/T 8163 | ASTM A106 | EN 10216-1 |

|---|---|---|---|

| Country | China | USA | Europe |

| Application | Fluid transport | High temp. & pressure | General & pressure fluid systems |

| Grades | 10#, 20#, Q345 | Gr. A, B, C | P235TR1, P265TR2 |

| Testing | Hydrostatic + visual | Hydro + NDT (often) | Hydro + optional NDT |

| Max pressure | Moderate | High | Moderate to high |

In many projects, GB/T 8163 can substitute ASTM A106 if pressure requirements are not too high and local engineering codes allow for it. For European clients, the closest parallel is EN 10216-1.

3. What are the chemical and mechanical requirements?

Buying Chinese pipes? Don’t overlook the grade—10# and Q345 perform very differently.

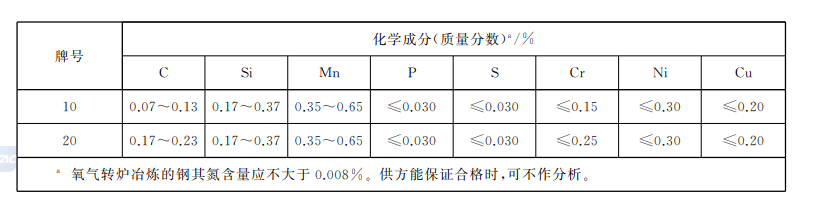

The GB/T 8163 standard defines chemical composition and mechanical strength for common grades like 10#, 20#, and Q345.

3.1 Common grades used under GB/T 8163:

| Grade | Description | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|

| 10# | Low carbon steel | ≥ 205 | 335–475 |

| 20# | Medium carbon steel | ≥ 245 | 410–530 |

| Q345B | Low alloy steel | ≥ 345 | 470–630 |

3.2 Chemical Composition (example: Grade 20#)

| Element | Max Content (%) |

|---|---|

| C | 0.23 |

| Mn | 0.35–0.65 |

| Si | 0.17 – 0.37 |

| S | ≤ 0.030 |

| P | ≤ 0.030 |

These properties make GB/T 8163 pipes well-suited for mid-pressure fluid transmission, especially in construction, municipal engineering, and light industrial systems.

Yige Steel supplies cold drawn seamless pipes with these grades, offering tight tolerance and high dimensional accuracy for hydraulic and gas transport applications.

4. Manufacturing process of GB/T 8163 pipes

Ever wonder how these pipes are made to such precise standards?

GB/T 8163 pipes are manufactured using hot rolling, cold drawing, or hot expanding methods, followed by required heat treatments.

Dive deeper:

The manufacturing process is a key factor in pipe quality. The GB/T 8163 standard allows flexibility in how the pipes are made—as long as the end product meets the chemical, mechanical, and dimensional requirements.

4.1 Three main processes:

- Hot Rolled (HR):

Suitable for large-diameter pipes. Less precise, but cost-effective for general use. - Cold Drawn (CD):

This is Yige Steel’s specialty. Produces pipes with:- Higher dimensional accuracy

- Better surface finish

- Thinner wall options

- Hot Expanded (HE):

Used to enlarge pipe diameter post-rolling, mainly for special size requirements.

4.2 Heat Treatment

GB/T 8163 allows for optional normalization, annealing, or stress relieving, depending on the steel grade and customer request. This flexibility helps match project needs in temperature or corrosion-sensitive environments.

5. Common applications of GB/T 8163 pipes

Wondering where GB/T 8163 pipes are actually used?

These seamless pipes are widely used in water, oil, steam, and air transportation systems across construction, industrial, and municipal sectors.

Dive deeper:

GB/T 8163 seamless pipes are designed specifically for fluid conveyance under non-extreme pressure or temperature conditions. Here’s where they’re commonly used:

- Oil & gas pipelines – For transporting petroleum products, diesel, and natural gas.

- District heating – Seamless pipes ensure consistent flow and no leaks in hot water supply systems.

- Chemical transport lines – In refineries and chemical plants for handling steam, solvents, or gases.

- Construction plumbing systems – Especially in high-rise buildings requiring strong yet lightweight fluid pipes.

They are not suitable for high-pressure boilers or steam turbines, which would require GB/T 5310-grade materials instead.

6. Inspection and testing requirements

Are GB/T 8163 pipes safe without full NDT like ASTM?

Yes—GB/T 8163 requires hydrostatic testing and visual inspections to ensure safety and performance.

Dive deeper:

Here’s a list of the common inspection methods under GB/T 8163:

| Test Type | Requirement |

|---|---|

| Hydrostatic Test | Mandatory for all pipes |

| Visual Inspection | Surface, ends, and markings |

| Dimensional Check | OD, wall thickness, length |

| Non-Destructive Testing (NDT) | Optional unless required by client |

Some international buyers request ultrasonic testing (UT) or eddy current inspection (ECT)—these can be done upon request at Yige Steel with certification.

Markings include:

Steel grade + standard + size + batch number

e.g. “20# GB/T8163 88.9×5.49×6000 mm”

7. GB/T 8163 vs GB/T 3087 vs GB/T 5310: What’s the difference?

Not all seamless pipes are created equal—choose the right standard.

While GB/T 8163 is for fluid transport, GB/T 3087 targets low-pressure boilers, and GB/T 5310 is for high-pressure steam applications.

| Standard | Application | Temp/Pressure | Common Grades |

|---|---|---|---|

| GB/T 8163 | General fluid transport | Medium | 10#, 20#, Q345 |

| GB/T 3087 | Low-pressure boilers | Low | 10#, 20# |

| GB/T 5310 | High-pressure boilers | High | 20G, 15CrMoG, 12Cr1MoVG |

GB/T 8163 remains the most cost-effective and flexible choice for non-critical fluid transport systems.

What should buyers pay attention to when sourcing GB/T 8163 pipes?

Buying based on spec sheets alone is risky—here’s what to double-check.

Always verify the supplier’s certifications, dimensional accuracy, and surface quality when buying GB/T 8163 seamless pipes.

Dive deeper:

Checkpoints before you place the order:

- Mill Test Certificate (MTC): Includes chemical, mechanical, and hydro test results

- Surface quality: Look for clean, rust-free, uniform pipes

- Size and tolerance: Ensure it matches your project’s required OD/WT/length

- Packaging: Seaworthy bundles, ends protected

Yige Steel offers cold drawn seamless pipes under GB/T 8163 with tight tolerances (±0.1mm) and supports MOQ as low as 1 ton—ideal for custom projects or prototyping.

9. Why GB/T 8163 is popular in international projects

Need seamless pipes fast without breaking the budget?

GB/T 8163 pipes are widely available in China and offer reliable quality, fast delivery, and flexible order quantities.

For overseas buyers, especially in Europe, Southeast Asia, and Africa, these pipes:

- Offer competitive pricing vs ASTM/EN products

- Are available in both metric and imperial OD

- Can often substitute ASTM A106 for non-code applications

Yige Steel has supplied GB/T 8163 pipes to clients in Germany, Vietnam, UAE, and South Africa for water treatment, HVAC, and gas pipeline projects.

10. FAQs about GB/T 8163

- Is GB/T 8163 equivalent to ASTM A106?

Not exactly. A106 handles higher pressure and temp, but GB/T 8163 can substitute in general fluid applications. - Can GB/T 8163 be used for boilers?

No. For boilers, especially under pressure, use GB/T 3087 or GB/T 5310. - What are the common pipe sizes?

1/2″ to 12″ (21.3 mm – 325 mm OD), wall thickness from 2 mm to 30 mm. - Is Q345 under GB/T 8163 same as ASTM A333 Grade 6?

Not directly. Q345 is a structural low-alloy steel. Compare with mechanical properties first. - Can I request UT or ECT testing?

Yes, Yige Steel provides optional ultrasonic and eddy current tests. - Do I need hydro test certificates?

Yes—it’s a standard requirement, and all our pipes come tested and certified.

Conclusion

GB/T 8163 is a trusted and practical standard for seamless steel pipes used in fluid transport systems. With multiple grades, strong mechanical properties, and flexible production options, it serves as a smart solution for both domestic and international buyers.

Ready to buy or need help interpreting specs?

Explore our products or request a custom quote here:

View Seamless Pipe Options

Understand Chinese Steel Grades

Contact Yige Steel Team