Worried about uneven pipe dimensions or poor surface finish? Cold drawing might be your hidden solution.

Cold drawing refines steel tubes at room temperature using a die, delivering precise dimensions, enhanced surface finish, and increased strength—unlike hot drawing, which sacrifices detail for speed.

Let’s dive deeper into what cold drawing really entails, how it contrasts with hot drawing, and why it matters for high-quality steel tubes.

What is Cold Drawing and Why Does It Matter?

Picture a candle pulled through a mold—cold drawing squeezes steel similarly, but with serious results.

Cold drawing is a cold-working process that pulls a steel tube or bar through a die at room temperature, refining dimension, finish, and mechanical properties effectively.

Think of cold drawing like forming a candle into a perfect, glossy tapered shape—you mold and stretch without melting. Technically, cold drawing involves pushing or pulling a steel bar or tube through a die (and often over a mandrel) at room temperature. This compresses and reshapes the metal’s microstructure, increasing tensile strength and hardness via work hardening—grain deformation under stress, as defined in “cold working” terminology .

The process may require multiple passes through progressively smaller dies, with intermittent annealing to reduce internal stresses and restore ductility. The result? Ultra-smooth, dimensionally precise tubes with tighter tolerances than anything hot processing can achieve. Typical advantages include Ø tolerance within ±0.01 mm, bright polished finish, and yield strength increases up to 20‑30% over hot-formed counterparts.

This method is crucial for applications like hydraulic tubing, precision mechanical shafts, seamless agricultural machinery pipes, and aircraft structural tubing. For such parts, roundness, concentricity, and fatigue performance are non-negotiable—cold drawing delivers.

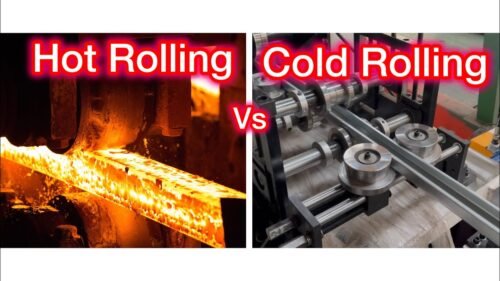

How Does Cold Drawing Compare to Hot Drawing?

Hot drawing is like rushing sculpting clay—quick but rough. Cold drawing is the artist’s slow, meticulous carve.

Hot drawing uses heated tubes to reshape quickly, but yields rougher surface, looser tolerances, and less strength than cold drawing.

To understand their differences, imagine sculpting clay while it’s hot versus carving jade slowly. Hot drawing heats steel above its recrystallization point, making it malleable and quick to shape through dies, ideal for large diameter reduction with low cost and high throughput. But as it cools, the tube shrinks unevenly, resulting in looser tolerances and a scale-covered finish that must be pickled or machined .

On the flip side, cold drawing stretches room‑temperature steel. This refines its surface and tightens tolerances — up to 20% stronger than hot-rolled steel. However, the trade-off includes higher processing costs and possible residual stress, requiring stress removal afterwards.

Key Comparisons: Cold Drawing vs Hot Drawing

| Feature | Cold Drawing | Hot Drawing |

|---|---|---|

| Temperature | Room temp (cold working) | Above recrystallization (>900 °C) |

| Tolerance | ±0.01 mm – high precision | ±0.1–0.3 mm – rougher |

| Surface Finish | Bright, polished, no mill scale | Rough, oxidized, requires cleaning |

| Mechanical Strength | ~20% higher tensile/yield strength | Lower, more ductile |

| Cost & Speed | Slower, multiple passes, higher cost | Faster, single pass, less expensive |

Hot Drawing uses, such as pipes for water systems or construction tubes, don’t need ultra-finish or tight tolerance. Cold-drawn variants, especially Drawn‑over‑Mandrel (DOM), are tailored for hydraulic systems, precision frames, or air‑pressure tubing.

What Data Supports Cold Drawing Benefits?

Numbers speak loud—draw forces show why cold drawing packs a punch.

Studies show cold rolling/drawing increases tensile strength by up to 20–30%, with drawing forces for steel tubes reaching ~160 kN at 47% reduction—improving hardness and precision.

Quantitative data validates cold drawing’s superiority. For example, drawing forces to achieve 47% reduction in cold‑rolled steel reach around 163 kN, showing significant plastic deformation and thus work hardening . Meanwhile, comparative tests reveal cold-finished steels can be up to 20% harder and stronger than hot-finished equivalents .

Industry data from hot vs. cold rolled steels indicates that cold-rolled variants retain internal stress, which, if not annealed, may lead to distortions during machining—something to be mindful of . That’s why many manufacturers include stress-relief annealing post-drawing to stabilize the microstructure—critical for precision part production.

When selecting steel tubes for high-pressure hydraulic lines, engineers rely on tensile strength >900 MPa and yield strength >700 MPa—specs achievable through cold drawing and quench‑temper cycles.

Conclusion

Cold drawing is the precision artist of steel forming—it delivers tight tolerances, smooth finish, and substantial strength compared to hot drawing’s rough and relaxed style. While costlier and slower, cold drawing is indispensable for high-precision applications like hydraulic systems, agricultural machinery frames, and aerospace tubing.