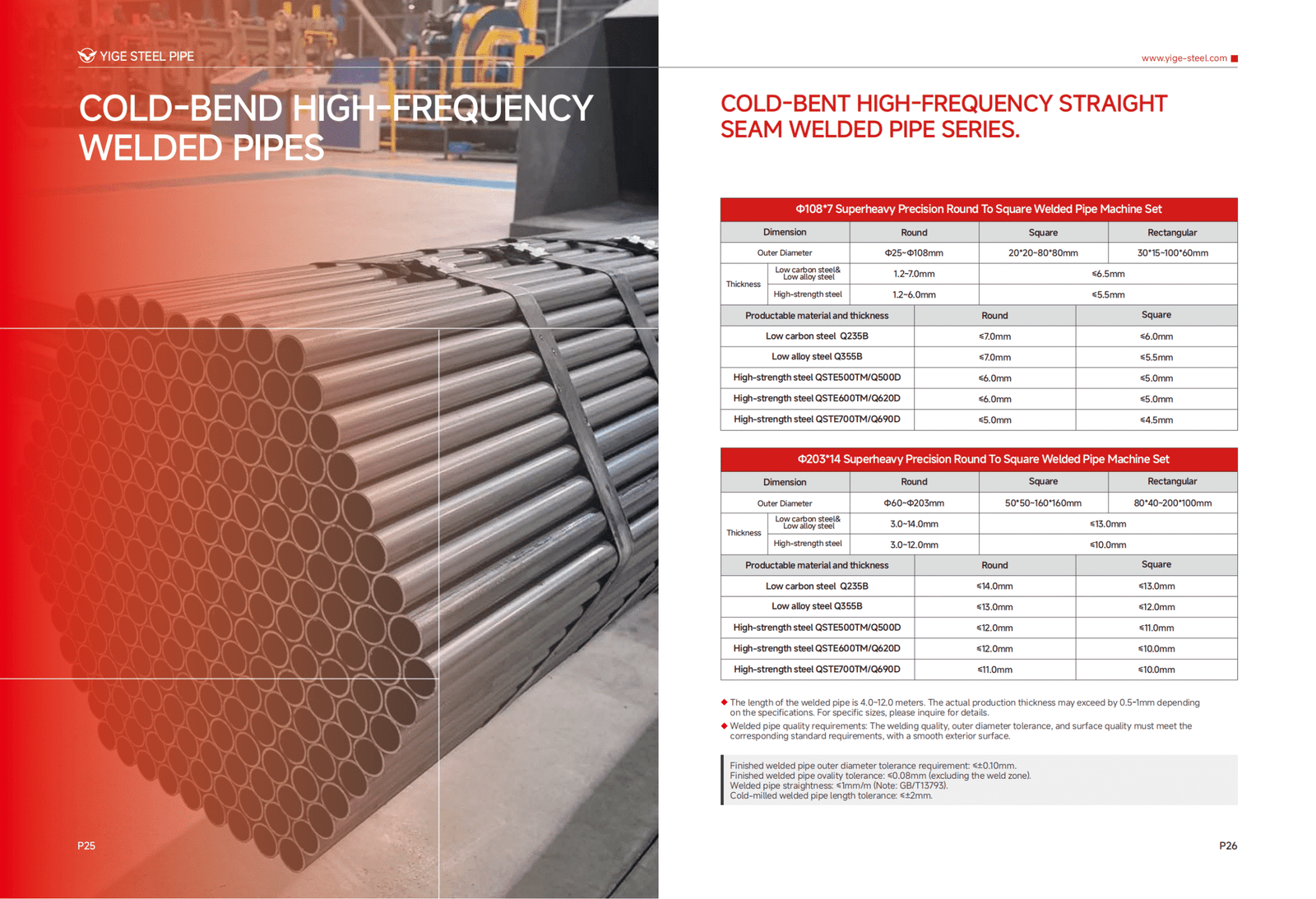

Product Specification

| Type | Cold-drawn Welded Round Steel pipe |

| Shape | Round |

| Surface Treatment | Bared, Black Painted, Galvanized, Oiled or to your requirements |

| Out diameter | 20-200mm, other sizes negotiable |

| Wall Thickness | 1.2mm-13mm , other sizes negotiable |

| Length | 2-16m or as request |

| Tolerance of OD | ±0.1mm |

| Tolerance of Straightness | ≤1mm |

| Technical Standard | GB/T 13793,GB/T6728-2017, GB/T3254, GB/T912,GB/T1591, GB/T16270,etc. |

| Material | Q235B/C/D/E,Q345B/C/D/E,Q390C/D/E,Q420C/D/E,Q550C/D/E, Q690C/D/E,370L/420L/440L/510L/550L/ 610L/700L/750L/800L,QSTE380-700, S355-960MC |

| Technique | Cold-bend High-frequency |

| Supply Ability | 5000 tons |

| Payments Term | T/T or L/C |

| MOQ | 1 ton |

| Delivery condition | As-Welded, Annealed, Normalized, Cold-Rolled |

Product Description

Cold drawn welded round pipes are welded steel tubes that undergo a precision cold drawing process. These pipes feature uniform wall thickness, tight dimensional tolerances, and smooth surfaces, making them suitable for high-performance industrial applications.

Application

- Aerial work machinery

- Transport vehicle

- Petrochemical machinery

- Ship and marine engineering

- Agricultural machinery

- Steel structure building

Product advantages

- Its internal and external surfaces are smooth and flat, and its dimensions are precise, ensuring excellent sealing and stability.

- The cold drawing process further improves the weld and significantly improves the strength of the pipe, making it perform well under complex working conditions such as high pressure and high temperature.

- Low manufacturing cost, widely welcomed by the market.

Available Mold

Customization

With in-house tooling, material sourcing, and technical support, we offer flexible customization to meet your specific needs:

- Dimension Customization: Non-standard diameter, thickness, and length

- Material Options: Carbon steel, stainless steel

- Processing Services: Cutting, logo marking

- Surface Treatment: Painting, shot blasting, oiling, galvanizing

- Marking & Packaging: Custom logo, labels, and packaging options

We support drawing-based production, small batch trial orders, and fast sample delivery to help your projects start quickly.

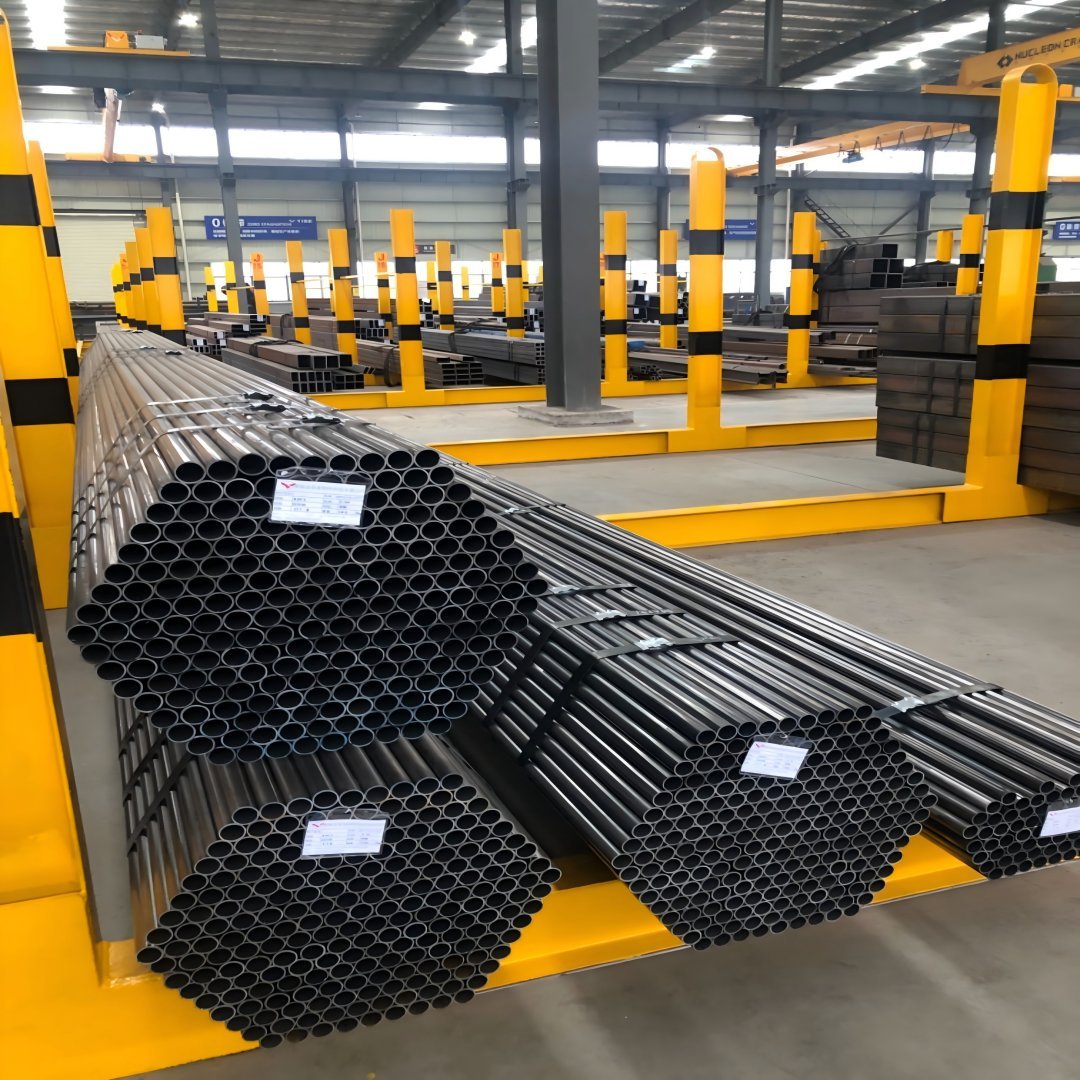

Packaging & Delivery

We provide professional packaging and flexible delivery options based on your product and shipping needs:

- Packaging Methods:

- Steel-strapped bundles with labels

- Plastic wrap + woven fabric cover

- Export-grade wooden cases or pallets

- Plastic end caps for tube protection

- Delivery Options:

- Sea freight, truck transport, or rail shipment

- Common ports:

- Shanghai, Changsha

- Lead Time:

- Standard sizes: 7–15 days

- Custom orders: 30–45 days

Export documents such as CO, CQ, and third-party inspection reports are available upon request.

CTA Section

Get Your Custom Quote in 24 Hour

EXTEND

Difference Between Cold-Formed Round Pipe and Cold Drawn Welded Round Pipe

| Item | Cold-Formed Round Pipe | Cold Drawn Welded Round Pipe |

| Forming Process | High-frequency welded, then cold-formed into round shape | High-frequency welded, then precision cold drawn |

| Surface Finish | Smooth and regular surface | Smoother finish with tighter dimensional tolerances |

| Dimensional Precision | Standard structural tolerance | High dimensional accuracy for precision applications |

| Mechanical Strength | Moderate structural strength | Higher mechanical performance and strength |

| Typical Applications | Architecture, furniture, handrails, poles | Hydraulic systems, automotive tubing, precision parts |

| Shaped Options | Mainly round shape | Available in round and special shapes (e.g. oval, hex) |

| Production Purpose | For general-purpose structures | For precision and performance-critical components |

Reviews

There are no reviews yet.