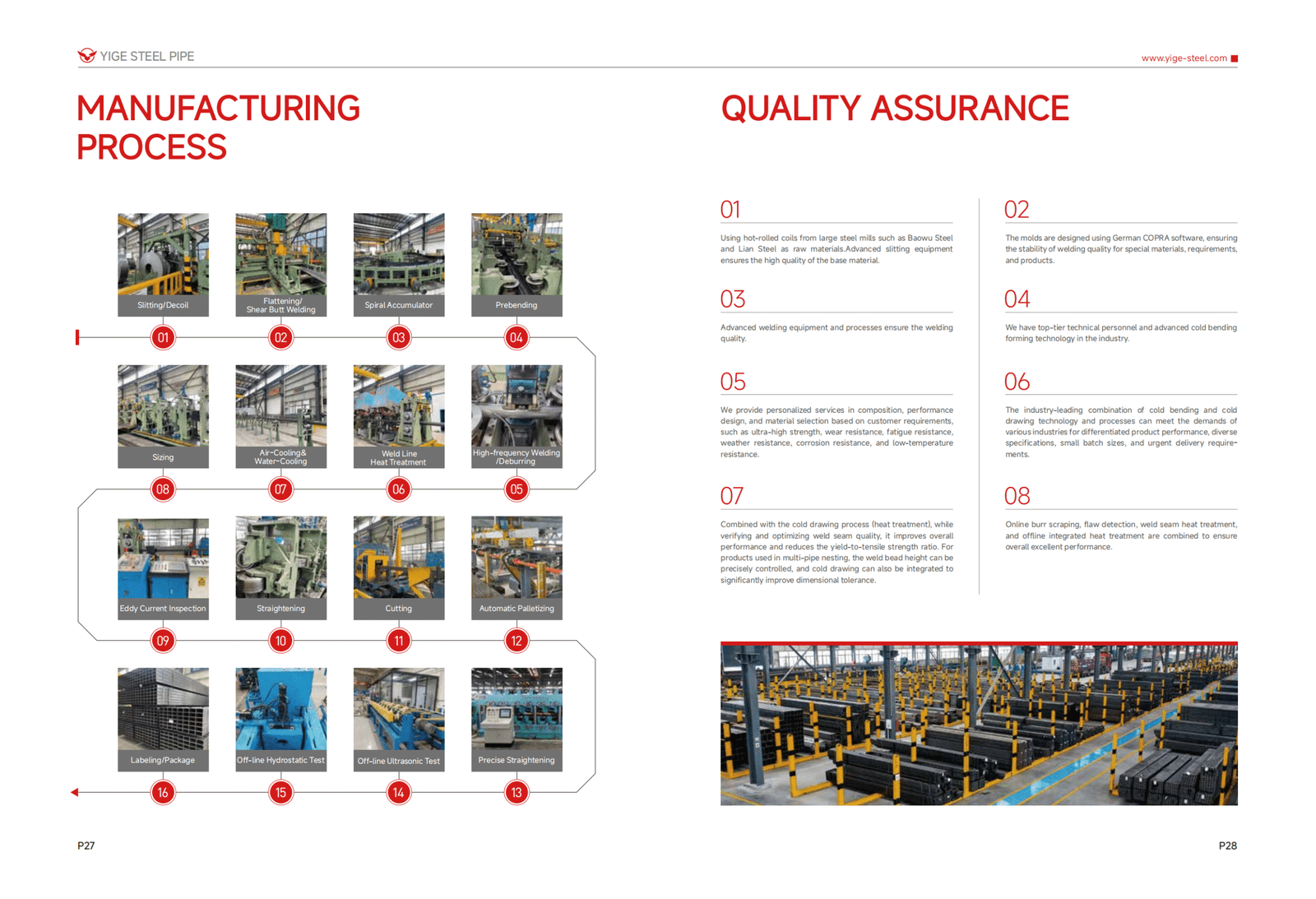

Product Specification

| Type | Cold-formed Round Steel Pipe |

| Shape | Round |

| Surface Treatment | Bared, Black Painted, Galvanized, Oiled or to your requirements |

| Out diameter | Φ25-Φ203, other sizes negotiable |

| Wall Thickness | 1.2mm-14mm, other sizes negotiable |

| Length | 4-12m or as request |

| Tolerance of OD | ±0.1mm |

| Tolerance of Straightness | ≤1mm |

| Technical Standard | GB/T 13793, GB/T6728-2017, GB/T3254, GB/T912,GB/T1591, GB/T16270,etc. |

| Material | Q235B/C/D/E, Q345B/C/D/E, Q390C/D/E, Q420C/D/E, Q550C/D/E, Q690C/D/E, 370L/420L/440L/510L/550L/ 610L/700L/750L/800L, QSTE380-700, S355-960MC |

| Technique | Cold-bend High-frequency |

| Supply Ability | 5000 tons |

| Payments Term | T/T or L/C |

| MOQ | 1 ton |

| Delivery condition | As-Welded, Annealed, Normalized, Cold-Rolled |

Product Description

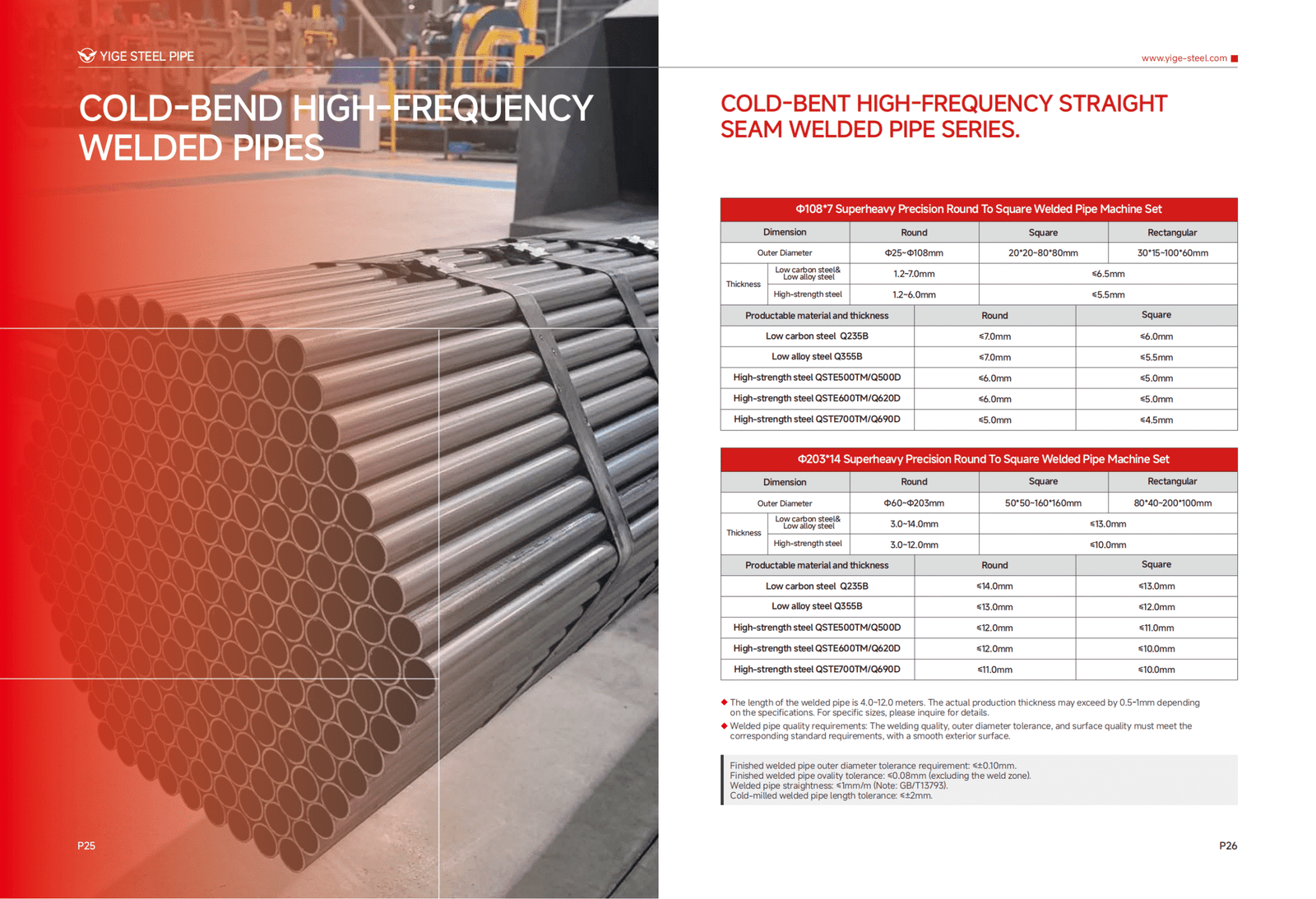

Cold-formed round pipes are made from steel strips that are high-frequency welded and then reshaped into round sections through cold forming. These pipes offer a clean appearance, consistent size, and are ideal for applications not requiring high pressure resistance but demanding structural uniformity.

Application

| 1. Steel structure building | Railway, Airport, Curtain Wall, Mobile Villa. |

| 2. Agricultural machinery | Rotary Cultivator, Harvester, Turnover Plow. |

| 3. Shipbuilding industry | Ships, Offshore Platform, Container Ships. |

| 4. New energy industry | Battery Frame, Photovoltaic Support. |

Available Mold

Customization

With in-house tooling, material sourcing, and technical support, we offer flexible customization to meet your specific needs:

- Dimension Customization: Non-standard diameter, thickness, and length

- Material Options: Carbon steel, stainless steel

- Processing Services: Cutting, logo marking

- Surface Treatment: Painting, shot blasting, oiling, galvanizing

- Marking & Packaging: Custom logo, labels, and packaging options

We support drawing-based production, small batch trial orders, and fast sample delivery to help your projects start quickly.

Quality Control

- Use coil plate produced by large steel mills such as Baowu and Lianyuan steel as raw materials.

- Advanced welding equipment and technology to ensure welding quality.

- The combination of on-line internal burr scraping, flaw detection, on-line weld heat treatment and off-line overall heat treatment can ensure good overall performance of the pipe.

Packaging & Delivery

We provide professional packaging and flexible delivery options based on your product and shipping needs:

- Packaging Methods:

- Steel-strapped bundles with labels

- Plastic wrap + woven fabric cover

- Export-grade wooden cases or pallets

- Plastic end caps for tube protection

- Delivery Options:

- Sea freight, truck transport, or rail shipment

- Common ports:

- Shanghai, Changsha

- Lead Time:

- Standard sizes: 7–15 days

- Custom orders: 30–45 days

Export documents such as CO, CQ, and third-party inspection reports are available upon request.

CTA Section

Get Your Custom Quote in 24 Hour

FAQ Section

Q1: What is ERW and HFW?

A1:ERW (Electric Resistance Welding) and HFW (High-Frequency Welding) are both methods of manufacturing welded steel pipes by using electric current to heat and join the edges of steel strips. HFW is actually a specialized, high-frequency version of ERW, offering improved weld quality and production efficiency.

Q2:ERW and HFW, which one has better performance?

A2: HFW is a high-frequency variant of ERW, offering better mechanical performance and more reliable weld seams. In modern steel pipe manufacturing, HFW is widely preferred for producing high-strength, pressure-resistant, and structural-grade welded pipes.

EXTEND

The Comparisons Between ERW and HFW

|

Category |

ERW (Electric Resistance Welding) |

HFW (High-Frequency Welding) |

|

Definition |

A process that joins steel edges using electric resistance. | A subtype of ERW that uses high-frequency current for heating. |

|

Frequency |

Range Low to medium frequency

(50 Hz – a few hundred kHz) |

High frequency (typically 100 – 800 kHz) |

|

Heating Method |

General resistive heating | Induction or contact high-frequency heating |

|

Weld Quality |

Basic weld quality, wider heat-affected zone (HAZ) | Superior weld quality, narrow HAZ, stronger joint |

|

Applications |

Light-duty or non-critical structures | Structural pipes, fluid transportation, pressure applications |

|

Cost |

Lower production cost | Slightly higher cost with better quality and reliability |

Reviews

There are no reviews yet.